Under the forge of the Motovilikhinskie Armories lies an iron slab of truly gigantic proportions. A century and a half ago, the 650-ton anvil, as part of the Tsar-Hammer, was recognized as a world treasure at the Vienna Industrial Exhibition. What was the effort behind this casting, unique in the history of metallurgy, and why is the invention resting deep underground today?

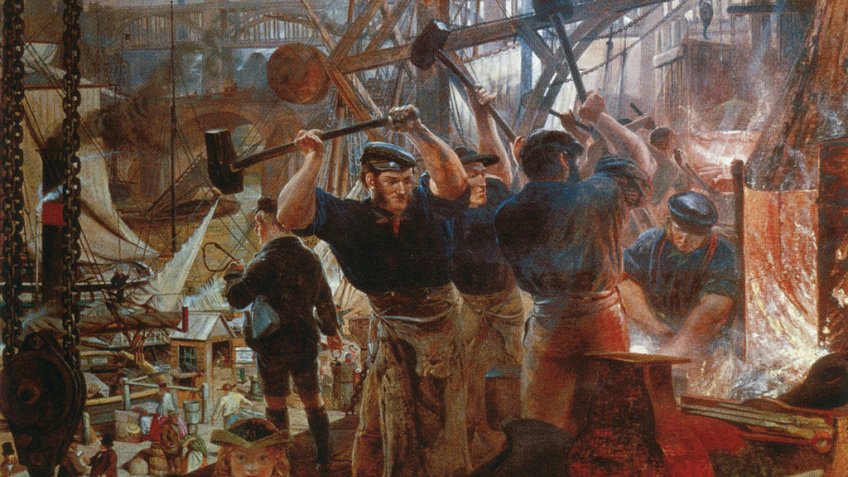

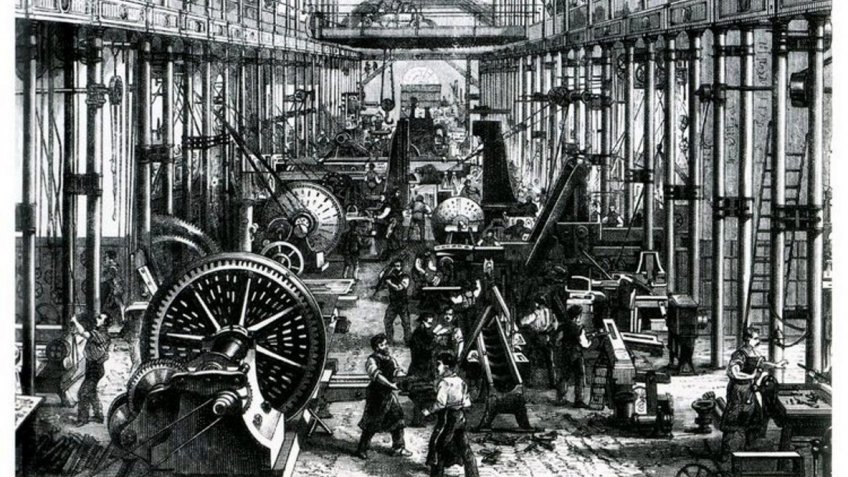

The second half of the 19th century went under the auspices of the Industrial Revolution. Large enterprises were built en masse, where manual labor was rapidly replacing machine labor. Competition between countries intensified, especially in such industries as metallurgy and machine building. The desire to be faster, more powerful and efficient, encouraged industrialists to daring decisions: to build the biggest ship, the fastest steam engine or the most efficient steam engine. Sometimes the record breakers were guided only by their own narcissism, but most often by industrial or military necessity.

When the international media broke the news that the British were plating their ships with 4.5-inch armor plates, the Germans were stamping 14-inch steel cannons, and the French were designing a hammer with a 100-ton drop for making blanks for artillery barrels, the Russians took this information as a challenge and an immediate threat to national security.

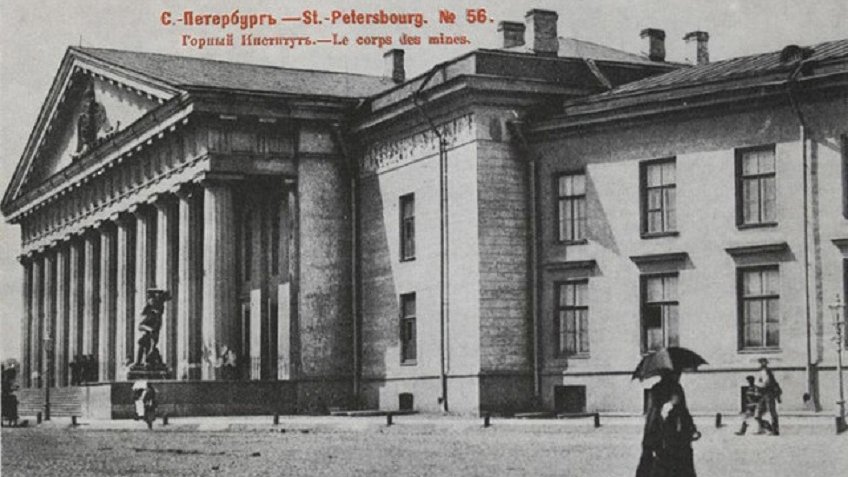

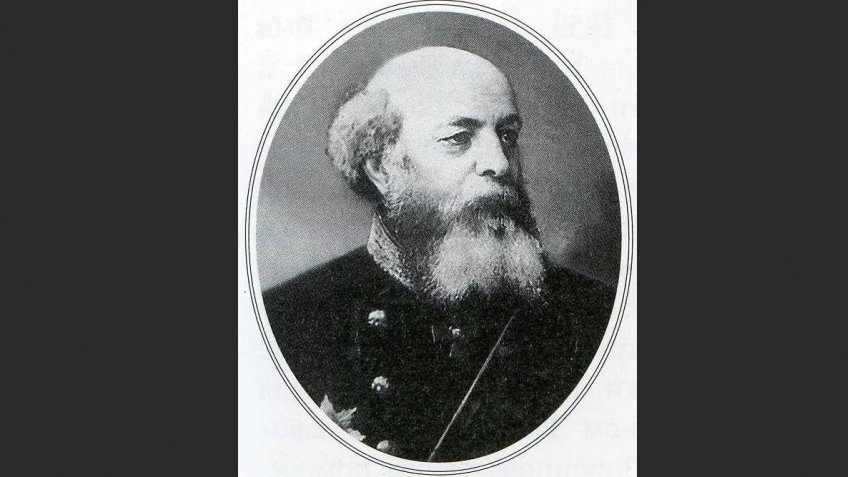

The decision was made immediately: to build an advanced steel-hammer factory in Perm. A young specialist Nikolai Vorontsov, a recent graduate of the Institute of the Corps of Mining Engineers in St. Petersburg, was appointed as the organizer and subsequent manager of the production. What was the reason for the authorities’ choice? Why did not they choose an experienced industrialist to fulfill a strategically important state order?

The young man was a perfect match. He was born in 1833 in the village of Kushvin Metallurgical Plant of Perm Province in the family of an artillery captain, so from his childhood he was a fan of weapons and military subjects. His grandfather, well-known mining engineer Andrey G. Iossa, who had served for more than 20 years at the Bogoslovsk plants, was conductive for his grandchildren getting a good engineering education and sent Nikolai and his brother to his own alma mater to study. Foremost national and European professors in metallurgy, mining, geology, chemistry taught at the oldest technical institute in the country, and the graduates of the Institute became senior managers of mines and factories.

After graduation and several years of work at the Zlatoust weapon plant, Nikolay Vorontsov took a three-year business trip abroad: he studied factory work in England, Belgium, Germany and France.

The last part in the recipe of an ideal engineer, an addition to good education and industrial and foreign experience, became his work under the direction of a major specialist. Having returned home in 1861, Vorontsov worked as a mechanic at all the Zlatoust plants, as a manager of the Armory and as an assistant to Pavel Obukhov at the Steel Factory. By that time Pavel Obukhov had already managed to make a revolution in the history of Russian artillery: he invented a method of mass production of high-quality crucible steel and supervised the production of guns in Russia, superior to the best German samples. The young researcher’s participation in the work of a recognized master had an impact on his later successes.

Two years later, in 1863, Nikolai Vorontsov was appointed the head of the construction of the Perm steel-tool plant. For 140 years copper was extracted and processed on the bank of the river Bolshaya Molotovikha, but by the mid-19th century the mines got exhausted, and the armory was erected in place of the former copper-smelting plant. A year later, it produced its first steel gun. Vorontsov remained in the Perm region to manage the new plant, because the main task, i.e., the production of large-caliber guns, had not yet been solved.

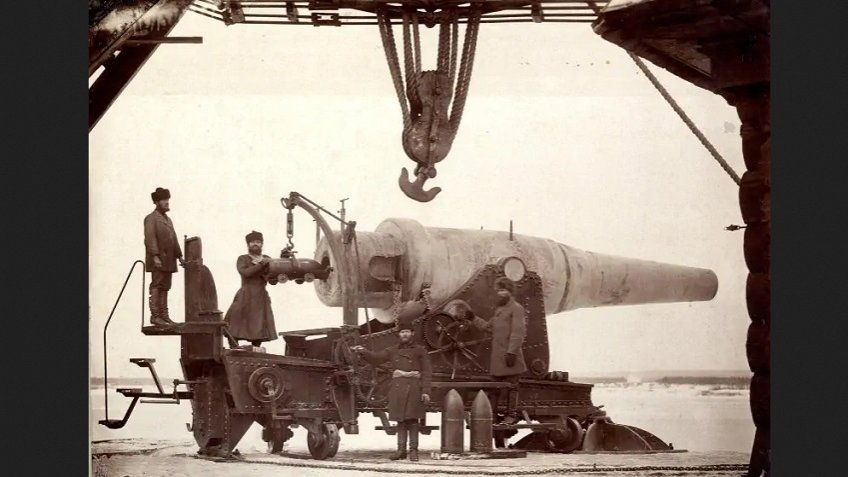

By that time Russia was producing 7-inch guns. Against the background of Italian 13-inch, German 14-inch and British 16-inch, our successes seemed rather modest. The mining engineer spent the next few years testing and improving technology. As a result, in 1868 Russia managed to start mass production of 8-inch guns. Considering the available equipment, this was the limit... To overcome it, more massive casting and forging hammers were needed.

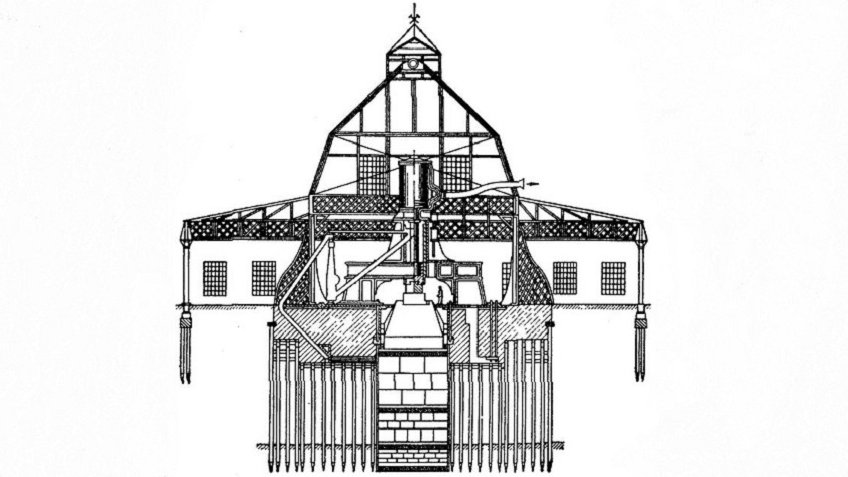

Nikolay Vorontsov began to design an unprecedented for that time hammer, which would allow to make a qualitative breakthrough in the armament business. In 1869, the calculations were ready, and the head of the Perm factory began to implement the plan. The first hydrogeological research of a suitable location showed that the anvil would have to be placed deep in the ground, taking into account the high ground waters of the Kama River and the sandy soil. It would be necessary not just to dig a pit, but to literally build a foundation that could withstand both the weight of the so-called “chair” (anvil or chabot) and the impact of the falling ram.

The depth of the pit was 12.5 meters. In addition, it was necessary to make an iron caisson in it. Then huge piles were driven in the ground, tarred wooden bars were put on the bottom, and there were several layers of hewn stones, weighing up to 150 poods, on the top of that. The “pie” was filled with hydraulic cement. And it was only a preliminary work!

The weight of the scaffold was to be 650 tons. And it was decided to make it not as a multipiece, but as a single piece. Naturally, it was impossible to move such a giant, so it was made directly at the place where the hammer was to be installed. The only manipulation that was planned was its overturn. The thing was that the strongest iron was of the first melting. It was supposed to take the brunt of the blow and be placed on top of the anvil. Therefore, the engineer provided two trunnions, and built the casting mold “upside down.”

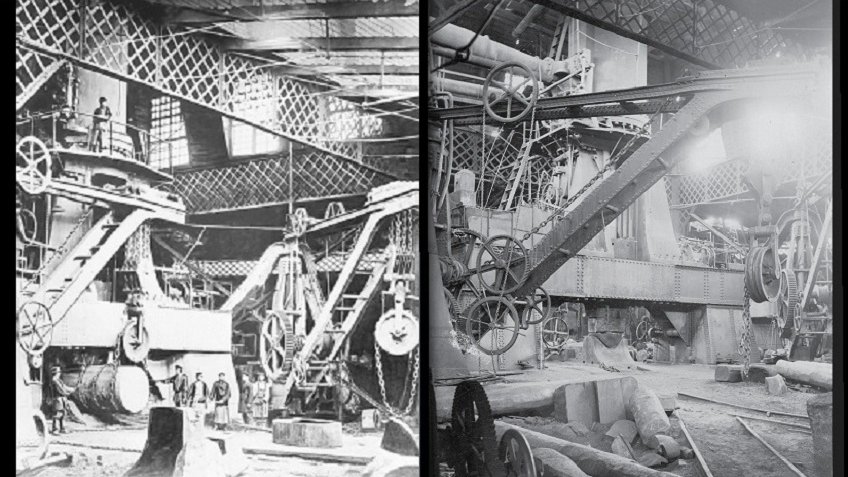

In 1871 the foundation was ready. The most demanding stage began. For casting, a whole metallurgical shop with fourteen cupolas was built, 700 workers were engaged. It took four melts and 27 hours of continuous work for hundreds of tons of iron to fill the mold. The ingot was so large-scale that its temperature was 700 degrees centigrade even a month later and more than 300 degrees centigrade after another month. It took 4 months to dismantle the mold, and then the “chair” was turned over and a 50-ton hammer was installed. The strike force of the hammer was 160 tons. According to Vorontsov’s project, the main difference of the Russian construction was the use of steam pressure not only to lift the falling ram, but also to accelerate its fall.

It became the largest double-acting steam hammer in the world, or as it was also called a “hammer with upper steam.” At the Vienna industrial exhibition in 1873, a working model of the “Russian miracle” was exhibited (in 1/6 of the real size). Nikolay Vorontsov was awarded the “Medal of Cooperation” - an award that was given to inventors whose contribution to science and technology was recognized worldwide. The construction of the grandiose construction with a total weight of 1,442 tons was completed in 1875.

At that time Nikolai Vorontsov was already a mining superintendent of Perm cannon plants - the steelworks and the cast-iron cannon plants. He never limited his to work with one project; he also actively developed the enterprises he had created. Thus, in 1876 it was here that the first open-hearth furnace in the Urals was started up.

In the same year, by order of the emperor, Vorontsov moved to St. Petersburg. His potential was needed in the capital city. He became a member of the Mining Council and the Mining Scientific Committee, in 1877-1883 he was the head of the Putilov Steel and Rail Rolling Plant in St. Petersburg, and from January 1885 until the end of his life he was the director of the Mining Institute.

And what happened with the main progenies of the master?

The hammer was in operation for more than 30 years. In the twentieth century, it was superseded by hydraulic presses, which achieved the same quality in metal processing at a lower design cost. The era of the “Tsar Hammer” is gone, but it was thanks to him that Russia began to independently produce large-caliber artillery.

The Perm plants, Vorontsov’s second “pet project," produced steam engines, steam engines and boilers, rolling mills, and other machinery. But its main specialization was and remains weapons. Every third gun of the pre-revolutionary Russia was branded with this trademark. During World War I, Motovilikha Plants supplied the Russian army with one-fifth of the artillery armament, and during World War II, they produced a quarter of all artillery systems of the Red Army. The side cannons of the cruiser “Aurora” were produced in Perm. Its work does not stop even today.