A digital modeling software complex began operating at St. Petersburg Mining University. This is a high-performance computing cluster, which allowed the university’s scientists to take their research to a fundamentally different level. Forpost found out what opportunities have opened up for them after the new laboratories were put into operation, and why the status of scientific organizations in the modern world largely depends on the availability of such platforms.

Why do we need modeling?

Creation of digital models provides for a more accurate understanding of the consequences of certain events, which with a certain degree of probability may occur in the future, like natural or man-made disasters. Their recreation in virtual reality is a complex process associated with the input of a huge amount of data into the computer system. However, the conclusions made by the operator on the basis of the results of the analysis, often allow making the best decisions, contributing to the growth of the level of safety of the population and infrastructure.

In many countries around the world, the military simulates entire battles in this way. This enables them to predict, with a high degree of certainty, what losses the army or navy will suffer during a clash with a potential enemy. Naturally, the prediction will be accurate only if the level of combat training and armament of both sides is known.

Rosatom reproduces, using super-powered software, such incidents as a plane crashing into a nuclear power plant. One such study can take up to six months, but in the end it will maximize the facility’s defenses. Even from such incidents, the probability of genesis of which in the real world is close to zero.

Experiments based on the creation of digital models are in demand by businesses. One of the most popular requests is to calculate the efficiency of equipment installed in production, or those installations which the company plans to buy. Customers are interested in how they will behave when interacting with certain metals or ores, and what their overhaul life will be.

It is of course impossible to prove the adequacy of simulation data without physical testing. But the computational process allows to significantly reduce their number. For example, if in the past it was necessary to crash a hundred cars to prove the flawlessness of a car’s safety system, now most of them are destroyed in virtual space. This allows manufacturers to save both time and money,” explains Yury Zhukovsky, Director of the Educational and Scientific Center of Digital Technologies at Mining University.

A new level of scientific experiments

Despite the pandemic, the St. Petersburg university decided not to postpone the creation of a new software complex until better times. It consists of three laboratories. Two of them are intended for students (after St. Petersburg universities return to full-time education), and the third is for serious scientific research and performance of business contracts.

The total cost of the center including investments in computers, servers, software, high-speed communication channels, repair of premises and other expenses is 63 million rubles. This is not a small sum of money, but it is necessary for the progressive development of the university and its positioning as one of the world leaders in the field of mining education.

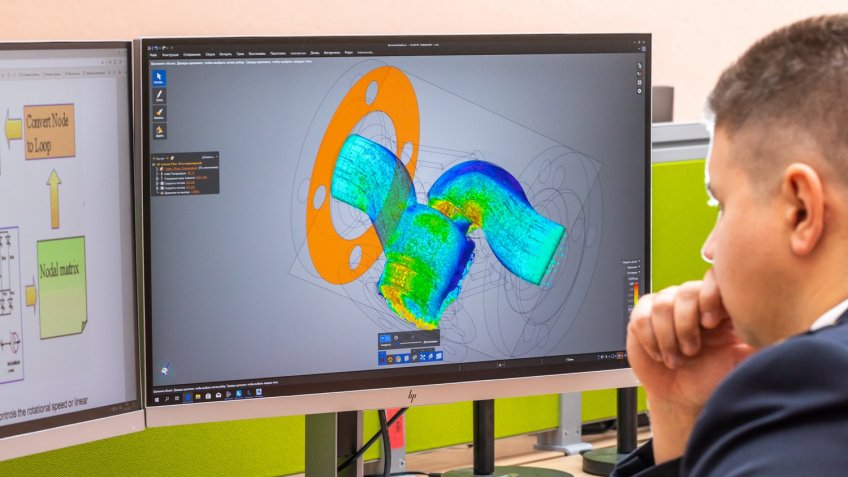

The cluster was opened quite recently, but the work is already in full swing. For example, one of the eight computers in the main laboratory is considered a model of an installation that receives two streams of liquids, i.e., warm and cold. The task is to understand what effect they will have on the metal in the long run. The other simulates a rock explosion (this process is an integral part of solid mining technology). The customer is interested in the optimum number of charges for the operation of a particular deposit. The third is the selection of the most rational arrangement of equipment for the plant for the production of solar panels. This will allow to avoid mistakes during its construction.

“Many people mistakenly believe that the program is capable of answering all the questions we are interested in on its own. This, of course, is not the case. Nothing will work without a human being. Moreover, data input and interpretation should not be handled by programmers, but by people with special competencies. Depending on what field of scientific knowledge this or that digital model belongs to, these are oilmen, mining engineers, designers or representatives of any other professions,” says Yury Zhukovsky.

The university’s nearest plans include a joint project with the French power engineering company Schneider Electric (specializing in solutions for increasing energy efficiency and automation of production). The partners are planning to jointly develop a smart mill (Smart Mill) for mining and processing plants, which will save energy without compromising the quality of the ore. The research in this area will begin with modeling the grinding process, and the result should be a reduction in the number of unscheduled equipment repairs at mining and processing plants that need to improve the efficiency of their process chains.

Enhancement of the quality of the learning process

The other two rooms have less powerful computers. These labs are not certified to provide paid services and are designed exclusively for students and postgraduate students. Anyone can work there, which, on the one hand, gives young people the opportunity to gain competencies in digital modeling and, on the other hand, separates the teaching process and scientific research, making the latter more productive.

"Any student at Mining University has the opportunity to use state-of-the-art engineering tools. This not only increases their competitiveness in the labor market, but also minimizes the adaptation time at the company after they get a job. At the same time, if we see that someone’s work is promising and the calculations it involves require access to more powerful computers, then this student can be admitted to continue experiments at the head laboratory,” stressed Zhukovsky.

It should be noted that as leaders in the software market in the field of digital simulation today are recognized two companies - the American Ansys and French Dassault Systèmes. In order to familiarize students with the software of both companies, the leadership of Mining University decided to buy both platforms. The university also uses similar domestic developments, but only for local calculations. For example, the Geomechanics Center uses them to model rock masses.