This fall marks the 250th anniversary of the founding of St. Petersburg Mining University. The corresponding decree was signed by Empress Catherine II on October 21, 1773 (old style). Forpost asked the rector of our country's first technical university, Vladimir Litvinenko, how relevant this decision was for the domestic mineral complex and what the consequences were.

- Vladimir Stepanovich, why was it necessary to open the college for mining engineers 250 years ago?

Vladimir Litvinenko: The 1870s was not an easy time for the Russian Empire. An incredibly difficult war with the Ottoman Empire was taking place in the south. In Poland, the Bar Confederation was raging. In the east the Pugachev rebellion, increasingly dangerous to the state, was beginning. Not only was there a growing demand for iron, copper, bronze, and other ore needed to produce armaments, but there was also an acute shortage of engineers. People who would be able to increase the output of the Ural metallurgical plants and organize their uninterrupted operation.

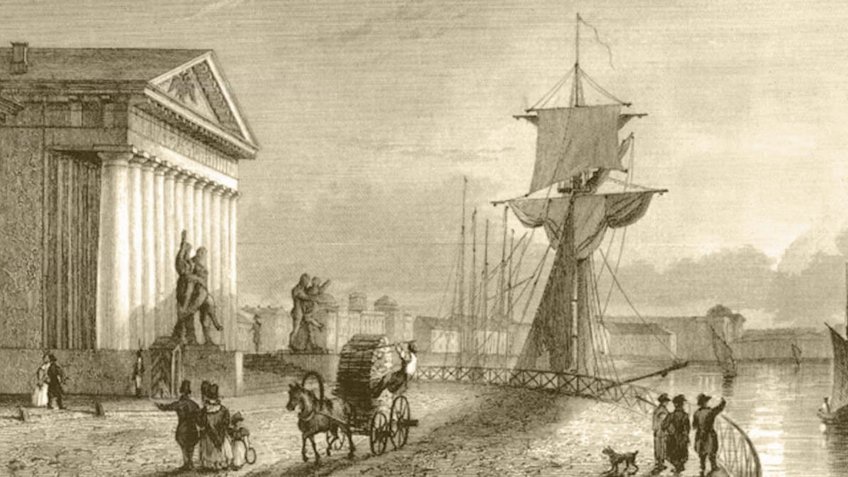

Foreigners were not eager to go far away and preferred to work in central Russia, closer to Moscow and St. Petersburg. And there was not enough competent personnel of their own, who had been educated abroad. So Catherine II, at the suggestion of Ismail Tasimov, a Bashkir industrialist who had escaped from Salavat Yulayev, made the only right decision in this situation: to start training engineers inside the country. It was for this purpose that the Mining School - the future St. Petersburg Mining University - was opened. By the end of the 18th century more than a hundred people were studying there.

- The history of mining itself in Russia began much earlier. Why didn't the state initially concern itself with the problem of training its own competent personnel?

Vladimir Litvinenko: Indeed, the first permission to search for ore and produce iron products from it was given by Ivan the Terrible back in 1576. And after the accession of the Romanov dynasty in Russia expeditions to the Urals and Siberia to search for deposits of minerals began to be organized on a permanent basis. But mostly iron and other resources were imported from abroad, from Sweden and Germany. In the Urals, the metallurgical production was carried out by artisanal method, the first factories appeared there only under Peter the Great, after his return from Europe in 1698.

In the central part of the country, weapons factories had started to be built much earlier, but they could not solve the problem of metal shortages. In addition, complicated logistics increased the cost of domestic resources and, as a consequence, government spending. Therefore, Peter's decision, which ordered the construction of plants in the vicinity of ore deposits, was the most logical. He was well aware that Russia is on the verge of an inevitable war with Sweden, and we need not only to increase the production of guns and other weapons, but also to make it less expensive.

As for personnel selection, the tsar ordered engineers to be sent to the Urals from Tula and Kashira. These were both foreign and Russian specialists who had received specialized education abroad, mostly in Germany. Such practice in the XVII and XVIII centuries was quite common. Incidentally, one of the young men who studied chemistry and mining in Freiberg was the world-famous Russian scientist Mikhail Lomonosov.

He did not, however, get on well with his teacher, Johann Genkel, and left Saxony in 1740 without completing his studies. But he managed to acquire there a whole set of competencies and fundamental knowledge. In particular, he got acquainted with the structure of mines, methods of fastening mines, hoisting machines, technological chain, he learned to distinguish minerals by their external signs. In many respects it was this experience that formed the basis of his book "The First Foundations of Metallurgy or Ore Works", which was printed by the Imperial Academy of Sciences in 1763. In fact, this is the first domestic textbook on mining, which became a handbook for all Russian engineers.

- Mikhail Lomonosov was an extremely versatile man. Were mineralogy and chemistry among his scientific interests?

Vladimir Litvinenko: Yes, of course. Immediately after his enrollment in the Academy of Sciences, he began to make a catalog of minerals, and later built a chemical laboratory of his own design, where he conducted experiments with samples of various ores, which came to the scientist from the Urals and other regions of the country. But the crowning achievement of his efforts in this area, of course, was his book "The First Foundations of Metallurgy or Ore Works." Mikhail Lomonosov began to write this manuscript much earlier, almost immediately after his return from Germany, but for various reasons, work on it was delayed.

It is impossible to overestimate the importance of this work for the mining industry. This is a brilliant even for today's times methodical publication, which clearly, systematically and in an accessible form outlines a huge scientific and practical material that allowed our mining industry to make a huge step forward. Lomonosov not only gave a description of minerals by their external characteristics, but also told, for example, how to determine the location of the lode by the pieces of ore found in the creek. He explained that rocks are colored in different colors from the presence of oxides of iron, copper, lead and other metals. For the first time he pointed out such factors as "satellites" of ores. For example, sulfur and arsenic pyrite are found next to gold deposits, and bismuth - to tin, and so on.

- Let us return to the Petrine era. It is believed that one of Peter's epochal decisions, which improved the efficiency of our mineral sector, was the creation of the Berg Collegium. Do you agree with that?

Vladimir Litvinenko: Yes, of course. This agency was established to manage the mining sector in 1719. Earlier this mission was assigned to the Orders of Mining, which had been established back at the turn of the century, but it was not a regulator of the industry, its job was just to control the sector. According to Peter's decree, the Berg Collegium became "a single judge of all... who searches, digs, smelts, cooks... all kinds of metals". Besides, it also acted as a modern credit institution, since "the one who invented new metals and minerals... and wants to build a plant, he will be given money for construction from the board, according to the kindness of ores looking at, to borrow.

Motivation of engineering personnel, who were exempted "from all extortions of money and soldiers' and sailors' service", pricing issues, protection of the state, which had the right to "purchase gold, silver, copper and saltpeter in advance of other merchants" - all these issues were the responsibility of the Berg Collegium. According to the founding document "Berg privelegium", signed by the emperor, it was a unified body of management and decision-making, which, incidentally, is greatly lacking in modern Russia. Today, in order to implement a project, its ideological inspirer often needs to obtain permission from several ministries at once, which, of course, complicates the task of creating full-fledged value chains within the country.

- The rapid development of the Donbas coal basin, which is among the largest in the world, began only in the second half of the nineteenth century. But steel, the production of which requires coal, was in demand even earlier. Why did it take so long to develop this province?

Vladimir Litvinenko: In fact, the decree on the search for ore deposits in this region was signed by Peter I in 1700. And in 1721, the Russian miner Grigory Kapustin, who led an expedition organized by the Berg Collegium, found large deposits of coal on the banks of the Northern Donets River. But it was impossible to begin their development for military and political reasons.

Despite the fact that the Crimean Khanate by that time had already lost its former power and could not, as under Ivan the Terrible, to besiege Moscow, raids on Bakhmut and neighboring lands were carried out regularly, almost every year. Periodically Crimean Tatars reached Izyum, Kharkov, and Voronezh Province. Therefore, the exploitation of the Donbas basin became possible only after the peninsula was annexed to Russia.

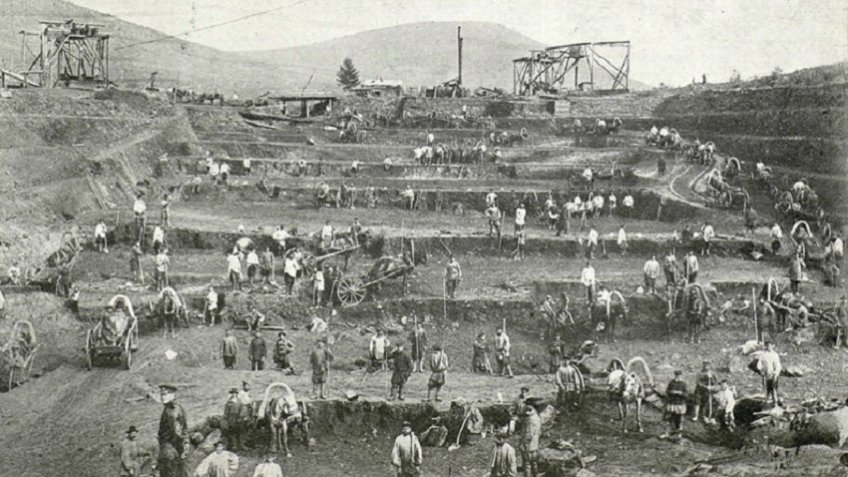

The first permission for coal mining and construction of the metallurgical plant in Lisya Balka (modern Lisichansk) was given by Catherine the Second in 1795. And in 1796 the first batch of coal was raised from the bowels of the Donbass. Russian mining engineer Peter Gorlov, after whom one of the cities in the region is named, described the deposit as follows: "It is rich in powerful seams, it is located very convenient for shallow mines and water-draining adits and moreover is located on the banks of the Donets River, which, according to experts, was very easy to make navigable."

As for the more rapid development of the Donbass coal basin in the second half of the nineteenth century, it was due to two main reasons. First, in 1856 Russia suffered its first defeat in the war for many decades. It happened mainly because of the poor quality of Russian artillery pieces. Their barrels simply could not withstand the intensive firing and literally fell apart. That is they could not make the same number of volleys as the British and French guns, which gave the enemy an advantage.

Accordingly, our metallurgists in the second half of the 1950s faced the most important task - to reform the industry and create more reliable alloys for armament production. It was solved by Pavel Obukhov, after whom the plant near St. Petersburg, built specifically to implement his ideas, is named.

He received a patent for his method of mass production of crucible steel of the highest quality in 1857. And tests of experimental samples began in 1860. They turned out to be very successful. No foreign gun, including the world-famous Krupp barrels, could surpass the limit of two thousand shots, and the Obukhov gun exceeded this result twofold.

Another, but more global, reason was the invention of the Martin furnace in 1864, which made it possible to produce steel of better quality than before. This dramatically increased the demand for both iron ore and coal needed for metal production. As a result, the resource base of the Donbass coal basin became much more in demand, its development accelerated, in connection with that in 1869 was founded Yuzovka - modern Donetsk.

- Around the same time, kerosene lamps began to be sold in stores, the raw material for which was petroleum products, rather than animal and vegetable fats, as in oil lamps. The new technology quickly gained popularity among the population and, as a result, provoked an increase in the demand for hydrocarbons. Oil production in the country increased in connection with this?

Vladimir Litvinenko: Yes, of course, in the seventies and eighties of the nineteenth century Baku experienced a real oil boom. Moreover, the production is carried out both from wells and from wells, as the raw material there is not far from the surface of the earth. According to the project of engineer Vladimir Shukhov, the first pipeline in the country was built, 10 kilometers long, leading from one of the local fields to the Nobel plant in the outskirts of the current capital of Azerbaijan. At the same time the first transport of oil by sea takes place.

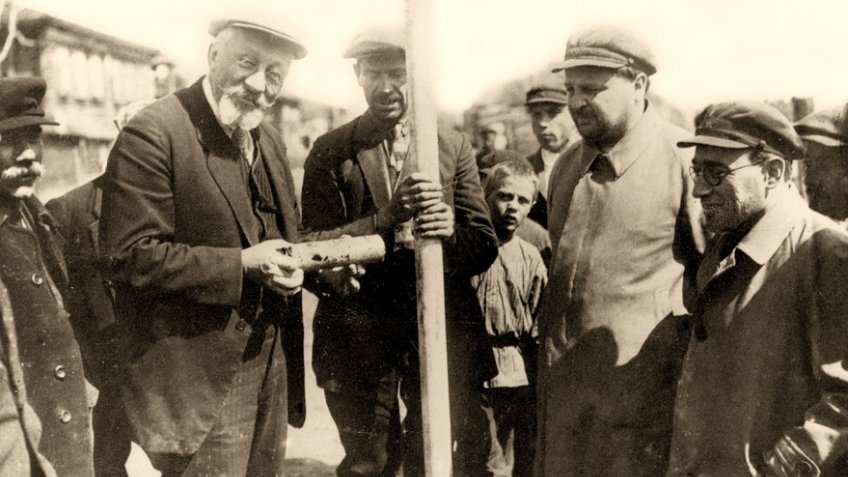

However, our refining industry lagged far behind American standards, which at the time were the highest in the world. In Russia only 30-35% of useful substance was extracted from oil, while in the U.S. - 65-70%. The first to pay attention to this were the founders of the Russian Chemical Society, Konon Lisenko and Dmitry Mendeleev. The result of their research and implementation of the results of this research into production was a sharp technological breakthrough, which allowed our country to catch up with the United States by the end of the 19th century in terms of production and quality of fossil fuel processing.

In the photo: the founders of the Russian Chemical Society. In the upper row, third right Konon Lisenko, second right Dmitri Mendeleev

- In Soviet times, the country already did not have enough of the volume of oil, which was provided by Baku oil fields. The Soviet Union was industrializing, requiring more and more raw materials. Was the discovery of the Volga-Ural oil and gas province a "gift of fate" that allowed Stalin's reforms to come to fruition?

Vladimir Litvinenko: That is partly true. Moreover, it was the beginning of the exploitation of oil deposits on the Volga and in the Urals foothills that allowed us to avoid a fuel shortage in the USSR during World War II and provide our army with fuel. This oil and gas field was called the "second Baku" and was discovered by Pavel Preobrazhensky, who also laid the foundation for the Russian potash industry and founded the Russian scientific school of salt geologists.

The scientist found the Verkhnechusovskoye deposit in 1929. Its reserves, however, were not too large and were exhausted after 15 years, but it was this discovery triggered the beginning of work in search and exploration for oil in the Western Urals. And led to the appearance of the Volga-Ural oil and gas province on geological maps. In the postwar years, it took the first place in the USSR by the number of produced barrels, surpassing the Baku. For example, in 1965 more than 71% of domestic oil was produced there. Now the degree of depletion of reserves there is about 65%. Nevertheless, Bashkortostan, Tatarstan, Perm Krai, Orenburg and Samara oblasts still produce about one-sixth of all "black gold" of our country.

As for industrialization, without which turning the USSR into one of the most high-tech powers in the world would have been simply impossible, it was based primarily on the famous GOELRO plan, a project to develop the electric power industry in Soviet Russia. It was developed in 1920 under the leadership of Vladimir Lenin, and a State Commission headed by Gleb Krzhizhanovsky was created to implement it in practice.

Most importantly, GOELRO was a development plan not just for the power industry, but for the Russian economy as a whole. It provided for the construction, next to new thermal and hydroelectric power plants, of enterprises vital to the modernization of our industry - the Stalingrad Tractor Plant, the Magnitogorsk Metallurgical Combine, Azovstal, the Volkhov Aluminum Plant and many others. Railroads were built at an accelerated pace, the development of the Kuznetsk coal basin, around which a new industrial region emerged.

As a result, the country saw a sharp increase in steel and iron smelting, rolled ferrous metals, paper production, and oil production. By 1937, during the first two five-year plans the production of cars in the Soviet Union increased 250 times, metal-cutting machines - 24 times, steel - 4 times, leather shoes and cement - three times. All this was made possible precisely through the implementation of the GOELRO plan.

- Nevertheless, many Soviet citizens, even in its heyday, could not boast of a high standard of living...

Vladimir Litvinenko: Yes, of course the Soviet Union was not an ideal model of social development. But professions such as military, doctor, teacher, scientist, engineer up until the 1990s were the real elite in our country. And the state was a regulator that mobilized society to solve specific problems. This approach allowed us to become a highly developed country. We were the first in the world to fly into space, build a nuclear power plant, invent the microwave oven, and create many other innovations that accelerated global technological progress. Other countries copied our educational standards because they considered them advanced.

I am by no means calling for the state to return to its function as an employer, as it was in Soviet times. It should undoubtedly remain in the hands of private companies. But historically, it so happened that the scientific and engineering thought in our country worked with maximum benefit for the socio-economic development of the country exactly in those periods when there was a unified body managing the mineral resource complex in the country.

But this is the backbone of any economy in the world, its foundation, without which no progress is possible. Throughout history, the dominance of one or another state was based on the ability of its representatives to extract minerals and involve them in deep processing in order to obtain unique products for final consumption. Mastering the deposits of gold, silver, copper, and iron gave impetus to the rise of Ancient Egypt under the Ramses, the expansion of the Qin Kingdom in Ancient China, and the conquests of Alexander the Great and Julius Caesar.

Modern technology is also completely dependent on natural resources. For example, a single battery for an electric car can weigh more than half a ton and require lithium, nickel, cobalt, and other metals and minerals to produce. To make a 5 MW wind turbine you need a huge amount of steel, almost a thousand tons. Plus copper, composite materials from which the blades are made, and so on. In other words, it is obvious that the high material-intensiveness of these and many other progressive industries will make the importance of the mining industry even higher in the future. This means that the need for competent personnel and breakthrough innovations will definitely not decrease.