The first technical devices began to be used in mining back in the 14th century. By the middle of the 18th century, the industrial revolution led to the replacement of tools such as picks, shovels, wedges and hammers, with albeit primitive, but machines.

Among the exhibits of the St. Petersburg Mining Museum there are models of famous deposits, for example, Blagodat Mountain (Grace). In the middle of the 18th century, large deposits of high-quality magnetic iron ore were found on the hill in the Tobol province (now Sverdlovsk Region). This fact was considered nothing more than the grace of God. And according to one of the existing versions, this is why the place received the same name. For the Russian industry, the discovery of such riches was indeed of particular importance, because at that time the mineral reserves in Siberia had not yet been explored.

Another model demonstrates the construction of the first large coal mine in Donbas. The scale of deposits in the area of the Donets River has been known since the time of Peter the Great. However, all attempts to develop them remained at the initial stages. Lands in the southern part of the country in the 18th century continued to be poorly explored and sparsely populated. Local coal was consumed mainly by sailors, who mined it by hand for their own heating. Although in other countries, they had began to use coke for smelting metal long before that, in Russia people remained faithful to charcoal.

Then the famous English engineer John Hughes managed to sign an agreement with the Russian government. The agreement stated that Hughes undertook the obligation to organize a joint-stock company for the extraction of coal in this area, to start the production of pig iron, and to establish the production of rails. As a result, the engineer managed to build the first large private metallurgical enterprise in the south of Russia and organize the smelting of pig iron and steel using local coal.

Karl Gascoigne is also considered a pioneer in the development of Donbas. At the invitation of Catherine II, he came from Europe to Russia and devoted more than twenty years of his life to the construction of metallurgical plants and enterprises if the country. The blast furnace built by an engineer at the Aleksandrovsky plant in Petrozavodsk made a real revolution in the national metallurgy. After all, its design used cylindrical bellows, allowing to pump air in a constant mode, thus maintaining the necessary temperature.

The collection of drilling equipment includes a model of one of the world’s first Mather & Platt mechanical drilling rigs of English production, a diamond drilling rig invented by one of the founders of domestic drilling, Sigismund Voislov, and an ice drilling tool used in Antarctica at the famous Vostok station.

Any mining industry cannot be imagined without power supply. In ancient times, the main source of power was the person or animals themselves. Then the power of wind and water gradually began to be used. One example of such an engine is a windmill donated to the museum by Emperor Alexander I. Later, water wheels, hydraulic turbines and steam engines appeared.

The renowned Russian engineer Ivan Tieme gained worldwide fame thanks to his own design of the hydraulic turbine, which he presented at the Vienna World Exhibition, where it was highly appreciated.

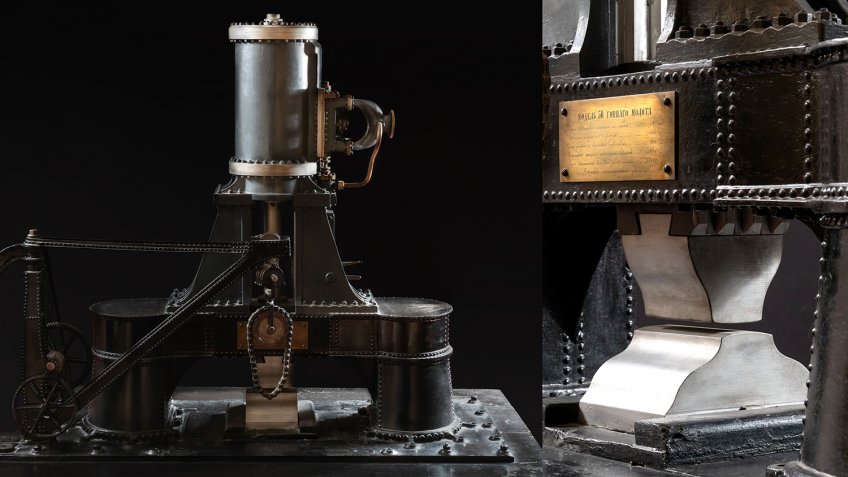

No less famous is Watt’s double-action machine, which was made by the renowned mechanic Bourdon, famous for creating a pressure gauge, which is still in use today. The invention of the machine itself greatly facilitated the system that existed at that time in mines, where the Newcomen steam plant had been used for pumping water for 50 years; it was a structure large in size and constant need of coal. Sometimes, to supply such a steam engine with fuel, fifty horses were involved. This unit was improved by James Watt. He made the piston in the new design move under the influence of steam. Thus, it was possible to increase its power simply by creating more pressure.

But mining does not end with the extraction of minerals from the depths. Another important stage is the enrichment of raw materials, when useful components are extracted from it. Austrian engineer Peter von Rittinger is considered a pioneer in the field of mineral processing. A jigging device had been used for enrichment for many centuries. It consisted of a barrel of water and a sieve on which the crushed ore was placed. As a result of the impact of the water jet, the material was separated. The grains, which had a high density, accumulated in the lower layer of the mass lying on the sieve. Elements with lower density were concentrated in the upper layer. Rittinger, on the other hand, derived a special formula that allowed to determine how long it would take for the particles to settle, depending on their size and density, and created a number of innovative dressing devices.

Gold washing technology also refers to devices for the beneficiation of raw materials. It was in Russia for the first time in the world that placer gold began to be mined on an industrial scale. It happened in the Urals at the beginning of the 19th century. During this period, a large number of original devices for washing sands were created in the country. Metallurgist Pavel Anosov designed a gold washing machine, which became one of the world’s first devices powered by a steam engine. As a result, gold production has increased significantly, the number of workers has decreased, and the loss of gold has reduced fivefold.

In addition, the Mining Museum houses the largest outside Germany collection of technical models made in the Freiberg workshops of mining machines of the mid-20th century. Among them are the MIVE single-bucket excavator, the first in the USSR, and the Donbas coal harvester.

← A rock falling from up above